Grew up taking things apart and haven't stopped finding better ways of rebuilding them.

My experience covers a broad scope of development levels, from initial concept generation through final manufacturing and production release. I have worked in wide array industries including Consumer electronics, Commercial Lighting, Research Experiments, and Industrial Robotics.

With this diverse set of experiences, I have an equally diverse network that I am able to call upon to add further context and insight to any project. During development, I am often able to incorporate final design and manufacturing elements early on which has helped to reduce turnaround time and production delays.

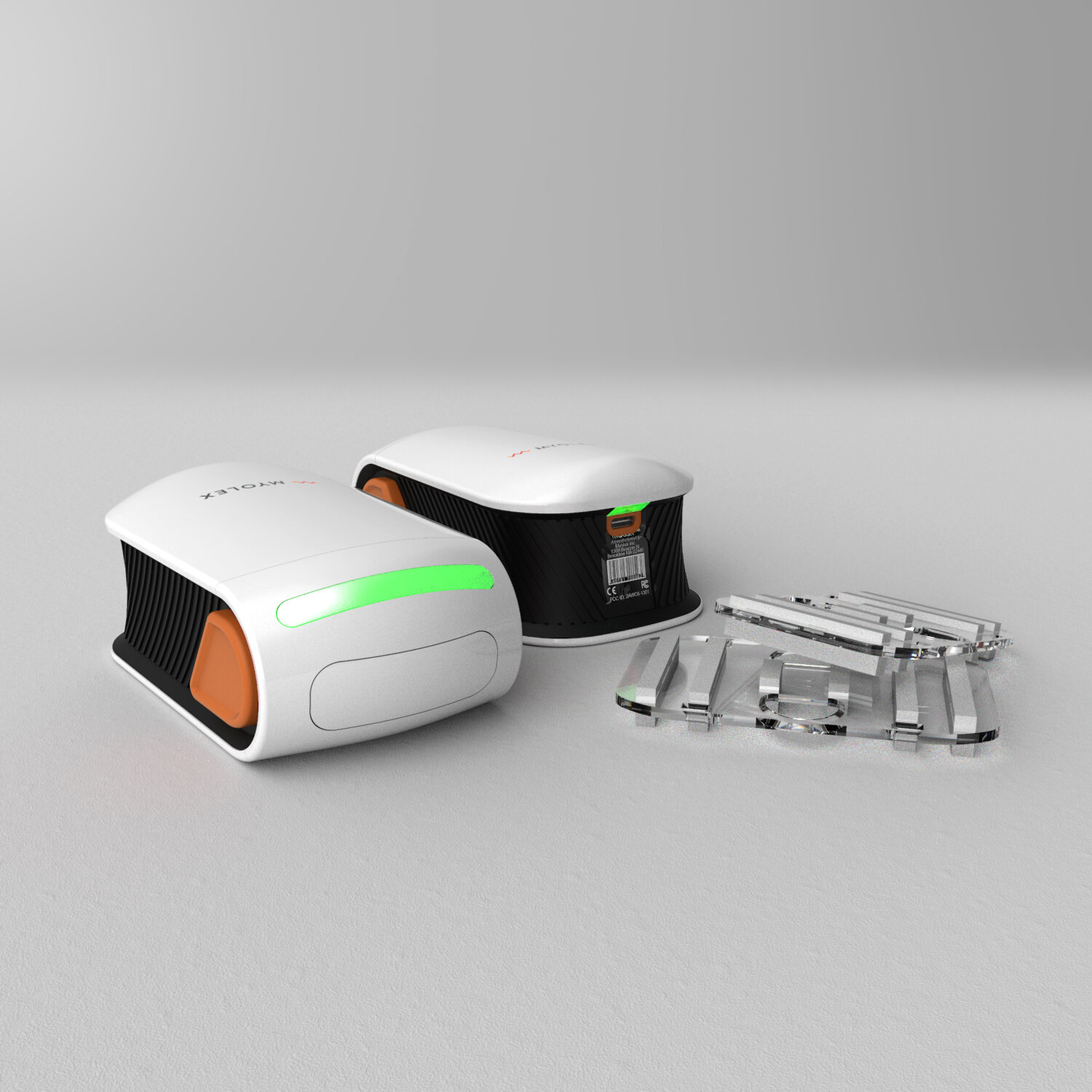

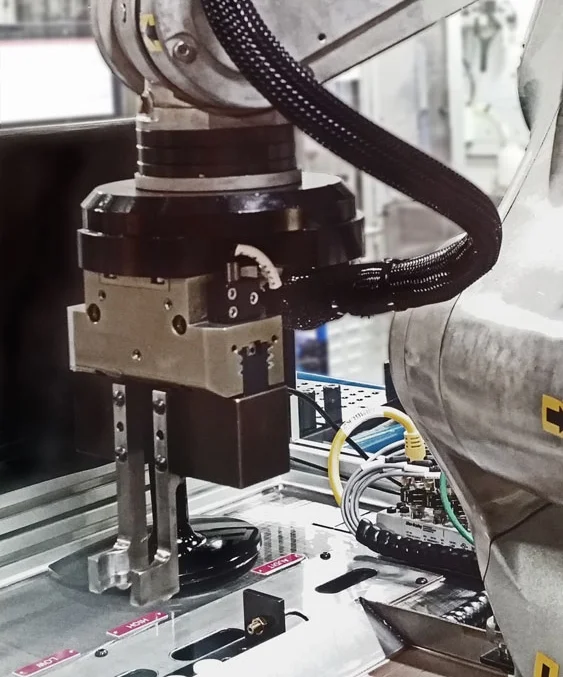

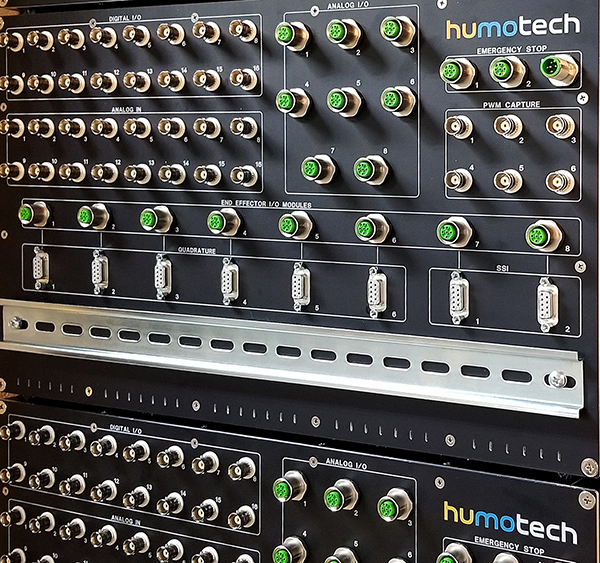

Previous Projects

PRICING:

Free initial consultation and scope of work definition.

Special pricing available for long-term or large scale projects.

Contact me with the form below for more information!

Send me an email with the form below, or set up an introductory meeting via Calendly.

Production Design Capabilities

Concept Generation

How will your product impact someone's life?

Problem Definition

Complete overview of product challenges - Monetary, Phsyical, and Legal

Feasibility Analysis

Probable production methods compared to desired functionality

User Experience Review

Evaluation of user interaction and avenues for implied instruction

Rapid Prototyping

What will your product look and feel like?

Digital Design

Extensive experience with Solidworks for the creation of complex digital designs for sales renderings and visual evaluation

Concept Validation

Assembly of inexpensive models exemplifying specific features or functions

Rapid iterative Design

Quick Turnaround, iterative designs specially made for your method of choice

Design For Production

Where will your product be made at scale?

Production Documents

Creation of final detailed drawings and CAD for manufacturers

Part Tracking

Development of numbering schemes for easy control and documentation

Tailored Design

Special attention to detail features specific to each method of assembly and manufacturing

+ Plastic Injection Molding

+ CNC Machining

+ Sheet Metal Forming

+ Composite Forming

+ Manual or Robotic Assembly

Product Line Improvement

Can your current production be more efficient?

Production Process

Low-Cost part revisions to improve efficiency and reduce production errors along with cycle cost review and analysis

Technical Documentation

Coordinating of documentation development with creation of step-by-step renders and graphics

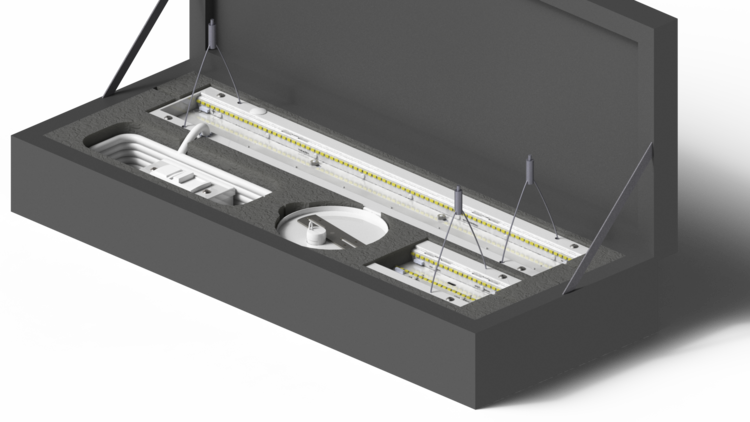

Product Packaging

Evaluation of user unpacking experience and shipping arrangement possibilities